By synchronising a real-time record of a toxic exposure with a video of the event, the subtleties of the effects of work practices and effectiveness of controls can be better appreciated.

A series of Pimex Videos is availble to viewing/download from NEPSI (a European Network for silica formed by Employee and Employer associations in 2006).

- Task sheet 2.1.12: Laboratory work;

- Task sheet 2.1.13: Local exhaust ventilation;

- Task sheet 2.1.14: Maintenance, services and repair activities;

- Task sheet 2.2.6 Crushing of minerals;

- Task sheet 2.2.10 Fettling larger castings in foundries;

- Task sheet 2.2.14 Glass furnace batch charging;

- Task sheet 2.2.22 Mixing of materials;

- Task sheet 2.2.30 Shot-blasting in foundries;

- Task sheet 2.2.36 Water-assisted dust suppression.

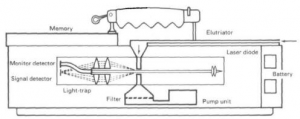

I started work in the area in 1980, with a chart recorder atatched to a Simslin laser based dust monitor, to look at the effect of work practices on uranium dust exposure while filling drums with “yellowcake” (actually a green-grey colour from the uranium oxides – uranium diurnate is yellow). The vertical placement of the lids on the 200L drums produced much of the expsoure due to a bolus of air pushed into the drum and then escaping. Changing to sliding the lids on the drums greatly reduced the dust.

I started work in the area in 1980, with a chart recorder atatched to a Simslin laser based dust monitor, to look at the effect of work practices on uranium dust exposure while filling drums with “yellowcake” (actually a green-grey colour from the uranium oxides – uranium diurnate is yellow). The vertical placement of the lids on the 200L drums produced much of the expsoure due to a bolus of air pushed into the drum and then escaping. Changing to sliding the lids on the drums greatly reduced the dust.

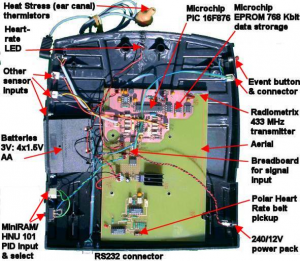

This eventually lead to my developming an 8 channel telementry system, with 8 hours of digital data recording – one of the channels was from a heart rate monitor to pick up the signal from a Polar heart rate band. The system used 430 MHz telemetry and the video from webcams was compressed on the fly and synchronised with the data streams.

Ideally, the process of editing a video should be able to be done at the time of recording, with statistics to show the expsoure attributable to each part of a process. This would allow immediate discussion of the exposure and leaving of the PIMEX record with the workplace.